In the packaging and packaging systems we find its main function and base, which is the packaging, the wrapper that contains the merchandise to group the products temporarily and thus facilitate their handling, transport and storage.

The Bottle Loaders works as a protection and guarantees the integrity of the goods throughout the process. In this sense, the tertiary packaging is the final layer that covers the product, and therefore the packaging is the last step in the production line.

Thus, there are numerous machines with different functions at the end of the production line and each of them is intended to provide a solution based on the needs of the product;

- Strapping machines

The strapping machine is a machine that seals the goods to each other horizontally, vertically or to the pallet. This strapping or lacing is carried out with a strap that surrounds the load.

The strap, as well as the strapping system, varies according to the merchandise, where the strap can be found in different materials depending on the weight of the load.

For example, heavy goods need a steel strap, and the food industry must have a hygienic strap with materials such as PET.

Bottle Unloaders machine function? The strapping machine surrounds the load with the strap to stabilize it during transport and handling, allowing a perfect reception by the customer. In this way, breakage and damage to the load are avoided.

The main applications of the strapping machine are:

Sealing of packages for shipping and transportation

Compacting and grouping of products

Grouping and joining of individual pieces of smaller or larger size.

Security sealed and sealed in boxes, wrappers and containers.

Fix the load directly on the pallet.

- Shrink / Shrink Furnaces

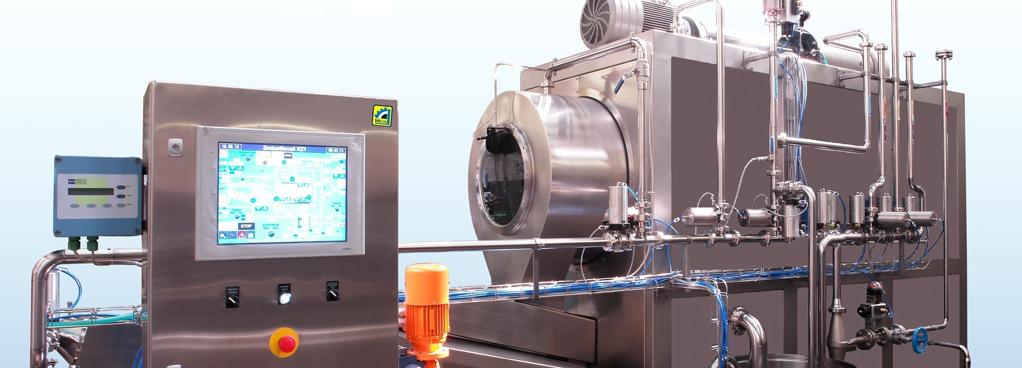

Shrink ovens or Crate Washers are machines that package or wrap the merchandise with a thermoplastic film.

This plastic wrap seals the product or load to the pallet, so that the merchandise is protected against dirt and other manipulations.

Shrinking means packaging a product with a film or transparent film that retracts and adapts to the shape of the product.

A shrink- wrap machine reduces costs in the product packaging process: it stretches the plastic film so that the amount of film used is saved

Retraction furnaces are used in various industries and can be found in different sizes, as well as with more or less automation.

- Hooded

The capper wraps and protects the load with an extendable plastic cover or film, in this way, the Centrifuges are protected against inclement weather such as rain, dirt and dust.

A hooded machine also performs shrink wrapping, which consists of sealing the wrapping, in this way it becomes inviolable.

It is a system for fixing merchandise to fixed trays, to make a waterproof load that can be stored abroad.

- Wrapper / Baler

It is an installation that packages the load and Churns it with a transparent plastic film that protects the merchandise from dirt and ensures stability during the transport and handling of the goods.

The wrapper is essential to save meters of the film that covers the load. Without the wrapper, up to 3 times more film is spent, in addition to not obtaining the necessary safety compaction for the merchandise.