The adequate liquid food container is undoubtedly one of the important factors that have the greatest impact on sales results. And it is, because beyond the presentation, the hygienic conditions in which this process is, is of vital importance. Therefore, it is really very necessary to use machines for liquid food packaging, adequate, modern and equipped with cutting-edge technology.

The machines for liquid food packaging become even more important when we delve precisely into the food to be treated. We talk about dairy products, fruit extracts, juices, soft drinks and even natural water.

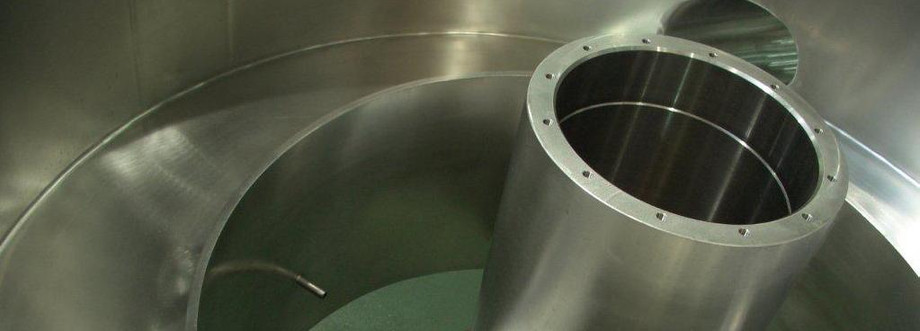

With continuous improvement and technology innovation, now the Butter Making Machines becomes more stable than before. While production efficiency has been greatly improved with the intelligent operating system, the operation is very simple and convenient.

And how to carefully choose the correct beverage filling machine

- First of all, you must determine what types of beverages you want to fill. Filling machine prices vary according to the range of your products. It is better to choose different filling machines for different types of products.

- Cost efficient is the first principle when you are going to buy Bottle Loaders. At present, the quality of the domestic food filling machine has enhanced in the quality much more than previous time. Choose a quality filling machine with stable performance, so that the packaging is faster and more stable, with low energy consumption.

- If there is a field for research, you should pay attention to the main aspects, but also pay attention to small details, because the details determine the quality of the machine in general. You should try to use sample machine as much as possible.

- A good reputation for an after-sales service, especially for food processing companies, is particularly important.

- Priority can be given to a trusted beverage filling machine and to the Bottle Unloaders.

- If possible try to purchase Crate Washers machines which have all accessories, simple operation and preservation, with automatic continuous feeding mechanism.

Utilities of machines for liquid food packaging:

- These machines are used for the proper container of milk and all its derivatives, juices in box or glass container, water, soft drinks, sodas, beers, wines, spirits etc.

- They have been designed to perform repetitive processes, without stopping for many hours in a row, which makes them suitable for eventually becoming part of an industrial automation process.

- The machines for liquid packaging reduce to zero the risk of contamination with waste and the possibility of leaks in the packaging.

How to choose machines for liquid food packaging?

The machines for liquid food packaging are presented in different versions, according to the type of container in which we are going to package. We have among many other options, the tetra pack, the cardboard box, the plastic bag, the glass container.

Each of these versions, in turn, is presented with options for daily production quantity, programming and automation options, process configuration etc.