Do you use boxes? In this case you need a sufficient amount of clean boxes every day. Once the quick and thorough cleaning is finished, the boxes will correspond to your hygienic standard and will return to the logistics and production process. You may need a box washer that allows you to deliver boxes in manual mode.

It is automatic and very versatile installations for washing and disinfecting boxes and baskets. They are suitable for all sectors of production and guarantee an unparalleled wash for any type of box.

The product range includes box washing facilities in a cabin or tunnel version, with the possibility to choose between several options: one, two or three tracks, horizontal or vertical.

- Crate Washers allow washing boxes of various types and formats, such as: folding boxes, rigid boxes, stackable boxes and baskets.

- Flexible hourly washing capacity, from a few pieces to 10,000 boxes per hour.

- They allow you to wash boxes of different formats at the same time.

Box washing facilities are fully automated and are manufactured following very high quality protocols, in addition to being designed and produced to measure to increase work efficiency and productivity. Before washing one can take help of Bottle Loaders to upload the bottles.

Box washer is of one or several different types. Washing machine is of small and large exterior dimensions. They are supplied to install separately or to integrate them into the production process.

Benefits:

Types of trays / boxes used throughout the food industry where they include: cooking trays, wire baskets, baking trays, distribution boxes and internal production trays.

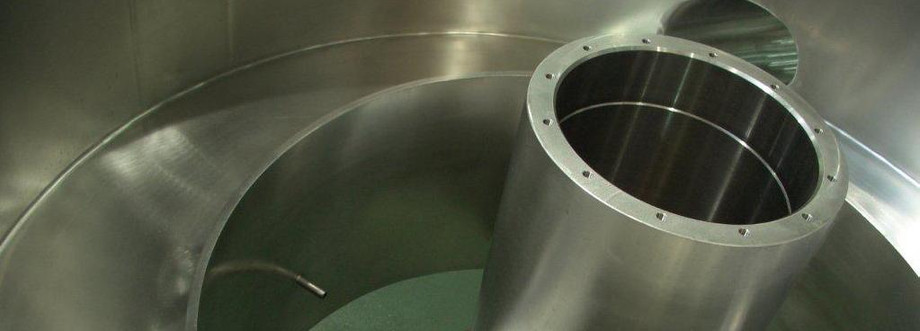

* Non-corrosive stainless steel design in components and contact parts,

* Content cabinet design to reduce water spillage

* Washing by high capacity stainless steel centrifugal pump for large washing requirements.

* Head of strategically concentrated spray nozzles, with removable design for easy cleaning,

* Double mesh filters to allow cleaning in operation, optional rotary filter for high solids applications.

* Easy access for maintenance of all operating components and adapt their configuration,

* Fully operational control panel with variable speed washing by time selector,

* A full range of standard options including return conveyors, Blow Units, and Dry Modules,

* Standard components available that include Allen Bradley controls.

Always optimal cleaning result

Do you work with boxes of different sizes and always want to achieve an optimal cleaning result? The width-adjustable high pressure injection system is exactly what you are looking for. This optionally available equipment ensures that the application distance is adapted to the width of the corresponding box to ensure a constant positive spray pattern.

Easy access

In the remote case that the operator has to intervene himself, he can do it quickly and easily thanks to numerous features: the doors located on both sides facilitate access to the internal space, in the area of the tanks there are manholes integrated and it is also possible to intervene from above thanks to the easily movable baffle plates. Similarly, the boxes can be easily removed with the help of Bottle Unloaders once cleaning process get complete.

No comments:

Post a Comment