The packaging is an integral part of the process. It fulfills two important objectives: to announce the product and protect it properly so that it is preserved for a certain period.

The package must meet a series of fundamental requirements, including:

- Containment

- Protection and conservation

- Communication

- Manufacturing facility

- The comfort of use

The main packaging techniques are:

Traditional packaging

Vacuum packed

Packaged in controlled atmospheres (EAC)

The packaging materials can be classified in the following groups:

Packaging for sale

The containers for the sale of the product to the consumer are those that contain the product, inform about it, and protect it during its use and domestic storage.

Containers for transport

They are the ones that protect the Butter Production Lines during transport and its distribution.

The containers must be filled with the precise amount of product to comply with current regulations. The effective closure of the package guarantees the maintenance of the quality of the packaged product during its useful life. The closure constitutes the weakest part of the container.

Closed

The closing operation consists of the union of the lid or closure with the container. The lid is the element that guarantees the duration and inviolability of the product.

Any of the following systems closes the containers:

Pressure closures: this type of closure is used for carbonated beverages. The cap can be cork, injection-molded polyethylene, crown cap, and aluminum screw caps.

Normal closures: these include cork stoppers with tin foil, aluminum caps, and aluminum foil caps.

Vacuum closures: they are used for preserves and jars of Butter Silos.

Vacuum packaging

Vacuum packaging is a technique that relies on the elimination of oxygen to reduce the proliferation of aerobic microorganisms that produce product degeneration.

IT IS NECESSARY:

- An enclosure that can be closed tightly.

- A vacuum pump

The types of vacuum packing machines are:

Vacuum packing machines for bags. It consists of a chamber that closes tightly and from which atmospheric air is completely extracted. They may be:

- Of a bell

- Double bell

- Automatic

Barlet sealers

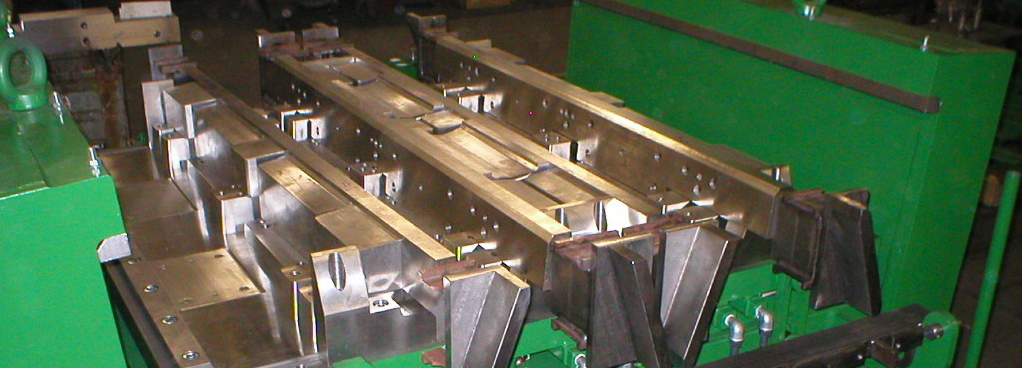

It is composed of a chamber or mold that closes tightly and consists of two parts; the lower part slides horizontally to be able to place the preformed barlets, previously loaded with product, in the corresponding alveoli. There are two kinds:

- Semiautomatic sealers

- Automatic sealers

Controlled atmosphere packaging (eac).

The technology of controlled atmosphere packaging (EAC) uses semipermeable films in association with a known composition of gas introduced into the container, which provides the desired internal atmosphere over the life of the product composition.

In the closed container, the level of oxygen will decrease, and the level of CO2 will increase due to the effects of the natural respiration of the raw vegetable.

If the Butter Making Machines were completely waterproof, the product would be altered quite quickly as a result of anaerobic glycolysis with low oxygen pressures.

There are two packaging techniques in modified atmosphere :

- Vacuum compensated

The vacuum technique is used to remove the air inside the container, and once removed, the protective gas is injected, and the film is heat-sealed.

- Bell packing machines.

- Butter Packing Machines

- Automatic packaging machines

- By sweep

This technique consists in displacing the atmospheric air of the container by sweeping the gas or mixture of gases to be used.