Butter Production Lines machines are used for the production of butter and cream, it has a container for the production of butter and cream. The capacity ranges between 50 and 300 l. It can be designed with one, two or three walls, as required. The inside of the container is made so that the butter does not stick. It includes a kneader and an agitator with hollow shaft worm gearbox. The energy is depends on the size of the tank. Main features

- We produce complete lines of butter processing, from cream tanks to final packaging equipment

- Butter machines for 10,000 kg of butter per hour

- Machinery for the production of butter in batches of up to 5000 l of cream

- With our continuous butter making machines not only butter can be produced, but also different types of spreads

- Low fat content of milk powder: 0.5%

- Long service life of the final product

- Our butter manufacturing lines are easy to use, compact and easy to maintain

It has different dosage units: Butter making machines can be equipped with different types of dispensers: for moisture, cultivation, oil (for the production of spreads), dry ingredients (mushrooms, herbs, cocoa, etc.) and salt grout. It can go in a straight line to the packaging machine. Butter Silos are integral to a flexible and continuous butter manufacturing process.

Benefits of Butter Production Line

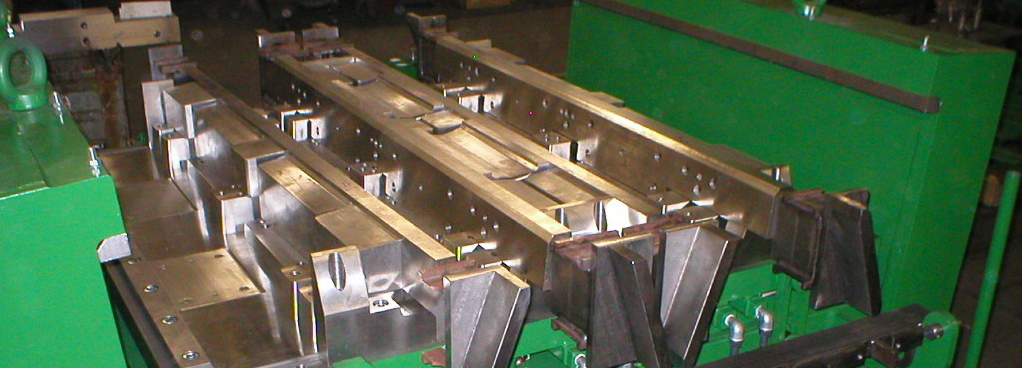

Improvements in the design of the plates in a working butter. The package of plates include the "turbulence services cape" mode achieved

- The plates are doing by the hydraulic cutting machine that excludes the occurrence of intension in the metal, welding operations is provided in the special stands.

- Knives are made of high density material.

- Rubber with improved quality indicators is used in manufacturing.

- Butter work is equipped with regeneration system, automated and equipped with an automatic defrosting system (protection against power outage or increase).

- Handler has improved functionality in terms of dispersion of the base and provides a stable phase of the final product.

- Specification of the process line is to include high semi-hermetic cream grease separators with centrifugal sediment discharge.

Butter Packing Machine

Butter Packing Machines are designed for wrapping butter in aluminium foil or parchment paper. The machines are offered with different capacities, each of them packaging the product in a predetermined dosage range. The product is loaded by a bunker with stainless steel screws. All machine surfaces that come into contact with the product are made of stainless steel. The capacity is easy to adjust by frequency converter and depends on the dose and the type of packaging (packaging 200-250 g, capacity 35-70 pcs. /min). Main features

- Products to be packed: butter, margarine, spreads edible fats, minced meat, curd, fresh cheese, and other pasta products

- Machine performance: 20 - 80 packages / min

- Package sizes: Machine modifications of 8 - 1000 g cover a wide dosage range and a wide variety of brick sizes

- Possibility of having different sized portions with a single machine, simply by adjusting the height of the brick

No comments:

Post a Comment